| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Huaqiang

Certification : ISO

Place of Origin : China

MOQ : 1 set

Price : US$40000-220000 per set

Payment Terms : L/C, T/T, Western Union, D/A, D/P, MoneyGram

Supply Ability : 50 sets per month

Delivery Time : 10-15 working days

Packaging Details : ISO CE 22KW-120kw Poultry Dung Organic Fertilizer Production Line Small machines are packed in wooden box,production line or large quality machines are packed in containers

Name : 20 Tph 380V 50HZ Organic Fertilizer Production Machine With New Type Organic Fertilizer Granulator

Machine type : Organic Fertilizer Granules making machine

Raw material : animal manure etc.,all kinds of organic materials

Product type : Machine for making organic fertilizer granules

Application : Organic Fertilizer Production Line

Capacity : 1-20tph

After-sales service provided : Engineers available to service machinery overseas,Field installation

20 Tph 380V 50HZ Organic Fertilizer Production Machine With New Type Organic Fertilizer Granulator

Introduction to organic fertilizer production line

Organic fertilizer production line is a kind of fertilizer production line, which is mainly process organic waste, animal manure into organic fertilizer. Honestly speaking, compared with compound production line, it is more complicated.

Raw materials of organic fertilizer production line

Agriculture waste: Such as straw, soybean meal, cotton meal, etc.

Livestock and poultry feces: Such as chicken manure, cattle, sheep and horse manure, rabbit manure.

Industrial waster: Such as wine less, vinegar lees, cassava lees, sugar lees, furfural lees, etc

Urban sludge: Such as river silt, sewage sludge, etc.

Working Process of organic fertilizer production line

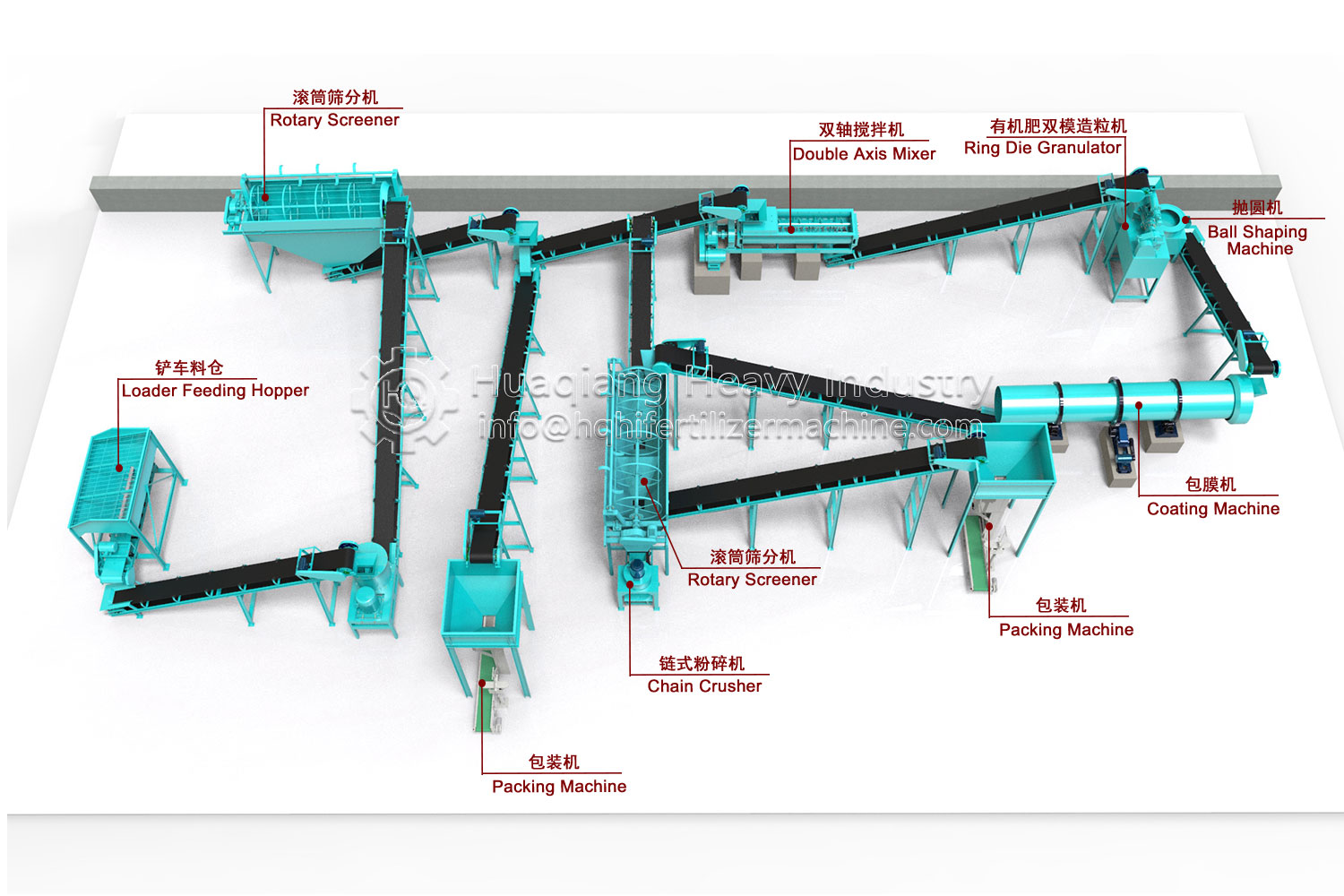

The organic fertilizer production line is mainly made up of compost turner, fertilizer crushing machine, mixing machine, granulation machine, drying machine, cooling machine, screening machine, organic fertilizer coating machine and automatic packager etc.

1. Fermentation process: Compost turner can thoroughly compost and turn high-stacked fermentation materials with large production capacity.

2. Crushing process: Semi-wet material crusher is widely used in the organic fertilizer producing process.

3. Mixing process: After being crushed, raw materials should be mixed evenly before granulating.

4. Granulating process: Granulating process is a core part in the production line.There need fertilizer granulating machine in this part.

5. Drying and cooling process: Rotary drum drying machine uses hot air to reduce the moisture content of fertilizers. The rotary drum cooling machine is used for cooling fertilizer with certain temperature and particle size in fertilizer industry. By the cooling process, the material can be removed about three percent of the water.

6. Screening process: After cooling, there is a still powdered material in the end products. All fines and large particles can be screened out using our rotary drum screening machine. Then, fines being transported by belt conveyor are back to horizontal mixer for remixing and re-granulating with raw materials.

7.Packaging process: This is the last process. Our automatic quantitative fertilizer packager is used for large-volume sub packaging of bulk materials, and is automatically weighed, conveyed and sealed in bags.

Main equipment in organic fertilizer production line

| Number | Name | Function |

| 1 | Compost turning machine | Used for fermentation of organic fertilizer raw materials |

| 2 | Half wet materials crusher | Crushing high water content organic materials |

| 3 | Mixer machine | Mixing organic fertilizer powder |

| 4 | Organic fertilizer granulator | Making organic fertilizer granules |

| 5 | Dryer machine | Drying organic fertilizer granules |

| 6 | Cooler machine | Cooling organic fertilizer granules |

| 7 | Screener machine | Separation of finished products and reclaimed materials |

| 8 | Belt conveyor | Carry on fertilizer raw materials and finished granules |

| 9 | Packing machine | Final products packaging |

Features of organic fertilizer production machine

1. This organic fertilizer production line is not only suitable for organic fertilizer, but also bio-organic fertilizer if a function bacterium is added, organic and inorganic fertilizer if nitrogen, phosphorus and potassium are added.

2. Widely application. The organic fertilizer production line can process different raw materials, such as animal manure waste, agricultural waste, ferment materials, etc. All those organic materials can be fermented and granulated into large-output organic fertilizers.

Advantages of organic fertilizer production machine

1. The whole production process is in easy operation, high-efficient production and stable performance. It is helpful to realize industrialization, marketization, and large-scale production.

2. With advanced technology, the quality of organic fertilizer is improved, promoting commodification.

Application of organic fertilizer production machine

Organic fertilizer production machine is widely used in waste processing.

1. Agricultural waste: corn stalk, wheat straw, leaves,etc.

2. Animal waste: chicken manure, pig manure, horse dung, sheep manure, etc.

3. Industrial waste: vinasse, bagasse, corn grit, etc.

4. Municipal sludge: domestic sewage, industrial sewage, water supply sludge and river sludge, etc.

|

|

20 Tph 380V 50HZ Organic Fertilizer Production Machine With New Type Organic Fertilizer Granulator Images |